[Previous page][Next page][Table of Contents]

12 . MONITOR

![]()

When performing such work as installing and removing the monitor, inserting and disconnecting the external connectors to and from monitor interior and the monitor, be sure to disconnect the power connector (plug) before starting work. Proceeding the work without following this instruction can cause electric shock or malfunctioning.

Using the monitor by converting it without obtaining a prior permission is not allowed. SEGA shall not be liable for any malfunctioning and accident caused by said conversion.

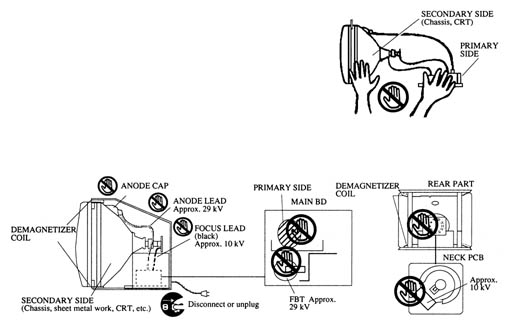

PRIMARY SIDE AND SECONDARY SIDE

The monitor's circuit which is divided into the Primary Side and Secondary

Side, is electrically isolated. Do not touch the Primary Side, or do not

touch both the Primary Side and the Secondary Side simultaneously. Failing

to observe the instruction can cause electric shock and this is very dangerous.

When making monitor adjustments, use a non conductive driver and make adjustment

without touching any part other than the Adjustment V.R. and knob. Also,

be sure not to cause a shortcircuit to the Primary Side and Secondary Side.

If short circuited, it can cause electric shock or malfunctioning, which

is very dangerous.

HIGH TENSION VOLTAGE

Some parts inside the monitor are subject to high tension voltage inexcess

of 20,000 volts and very dangerous. Therefore, do not touch the monitor

interior. Should soldering & paper wastes, etc., be mixed in the monitor

interior, turn power off so as not to cause malfunctioning or fire hazard.

CONNECTING THE CRT AND PCB

For combining the CRT and PCB, use specified part no. to maintain the

status of adjustments made at the factory. The anode of the CRT itself will

be accumulatively charged as time elapses, generating high-tension voltage

which is very dangerous. The monitor should be used with the Chassis, CRT

and PCB assembled. When repair, etc. is required at the time of malfunctioning.

Be sure to send it in an "as assembled" condition. If these are

disassembled, what's charged to said high tension voltage can be discharged,

causing a very hazardous situation. Therefore, under no circumstances should

it be disassembled.

STATIC ELECTRICITY

Touching the CRT surface sometimes causes you to slightly feel electricity.

This is because the CRT surfaces are subject to static and will not adversly

affect the human body.

INSTALLATION AND REMOVAL

Ensure that the Magnetizer Coil, FBT (Fly-Back Transformer), Anode Lead

and Focus Lead are not positioned close to the sheet metal work's sharp

edges, etc. and avoid damaging the insulated portions so as not to cause

electric shock and malfunctioning.

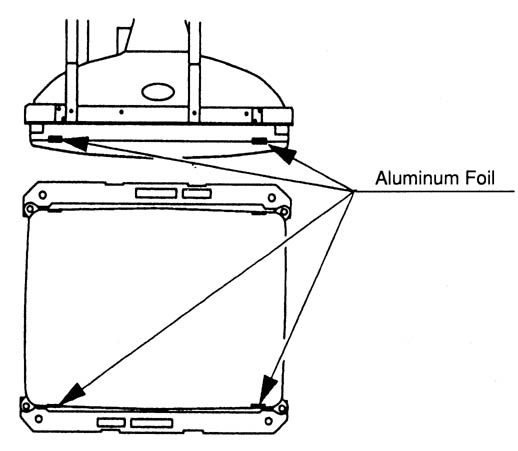

![]() For the purpose of static prevention,

special coating is applied to the CRT face of this product. To protect the

Coating, Pay attention to the following points. Damaging the coating film

can cause electric shock to the customers. For the caution to be heeded

when cleaning, refer to the Section of periodic inspection table.

For the purpose of static prevention,

special coating is applied to the CRT face of this product. To protect the

Coating, Pay attention to the following points. Damaging the coating film

can cause electric shock to the customers. For the caution to be heeded

when cleaning, refer to the Section of periodic inspection table.

Do not apply or rub with a hard item (a rod with pointed edge, pen,

etc.) to or on the CRT surfaces.

Avoid applying stickers seals, etc. on the CRT face.

Do not remove aluminum foils from the CRT corners. Removing the aluminum foils can cause static prevention effects to be lowered.

CAUTIONS TO BE HEEDED WHEN CLEANING THE CRT SURFACES

Static preventive coating is applied to the CRT surfaces. When cleaning,

pay attention to the following points;

Peeling off static preventive coating can cause electric shock.

Remove smears by using a dry, soft cloth (flannels, etc.). Do not use a coarse gauze, etc.

For smear removing solvent, alcohol (ethanol) is recommended. When

using chemical detergent be sure to follow instructions to follow;

Dilute chemical detergent with water and dip a soft cloth in and the thoroughly

wring iot to wipe smears off.

Do not use chemical detergent containing abradent, powder or bleaching agent.

Do not use alkaline chemical detergents such as "glass cleaner"

available on the market or solvents such as thinner, etc.

Do not rub or scratch the CRT face with hard items such as brushes, scrub brush, etc.

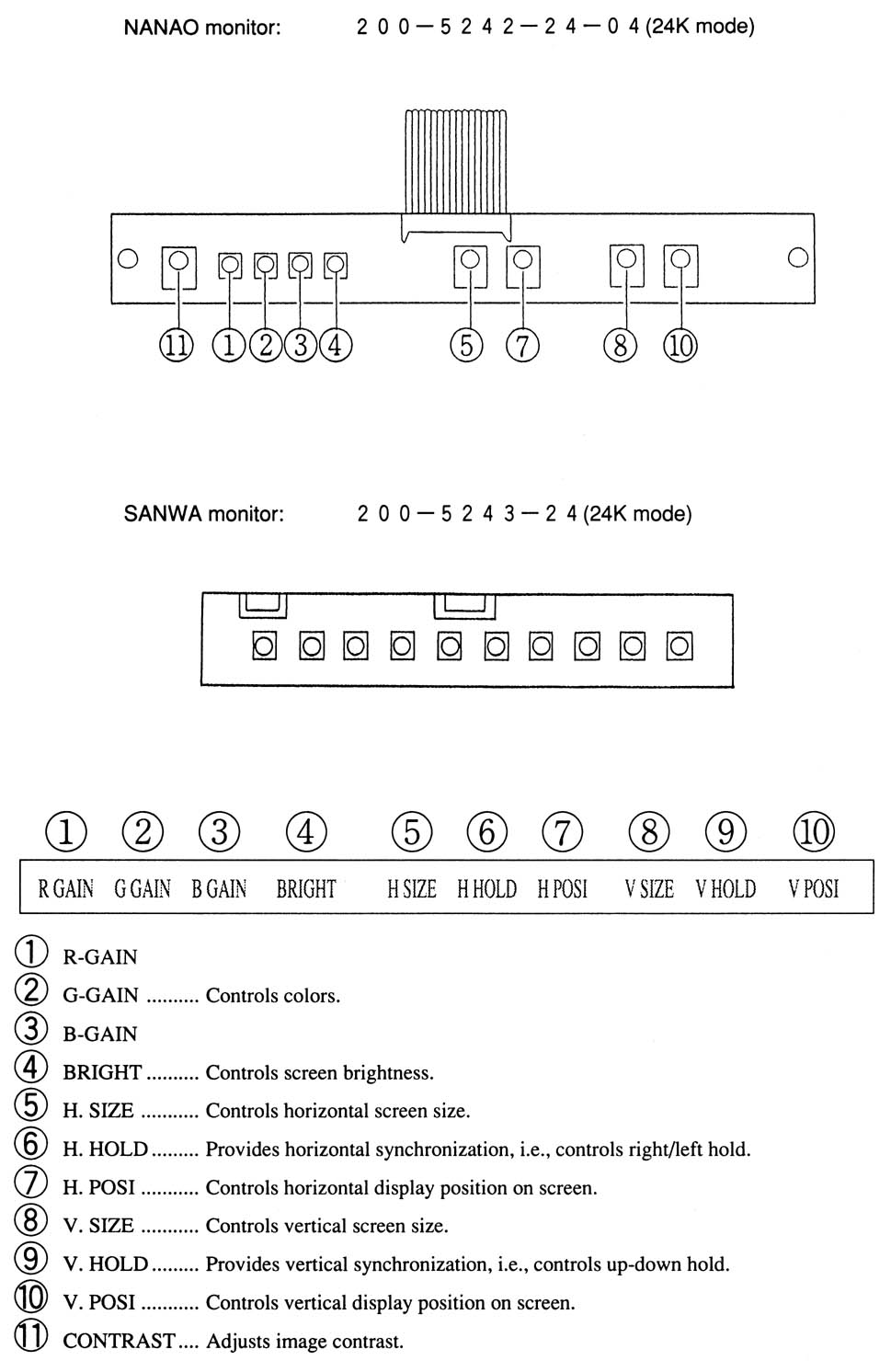

ADJUSTMENT METHOD

Monitor adjustments have been made at the time of shipment. Therefore, do not make further adjsutment without a justifiable reason. Adjusting the monitor which contains high tension parts is dangerous work. Also, an erroneous adjustment can cause deviated synchronization and image fault, resulting in malfunctioning. When making adjustment, utilize a resinous Alignment rod. Servicing with bare hand or using conductive tools can cause electric shock.